Spike Flow

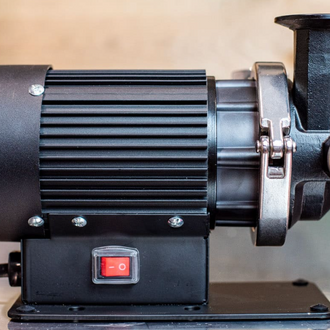

It's time to go with the (higher) Flow. With features like an Air Relief Valve (ARV), 6-vane impeller design, stainless steel precision machined casting and an integrated impeller shaft and thrust bearing, the Flow is the newest and most badass pump to hit the market.

*U.S. ONLY - Free Shipping for orders over $150

Overview

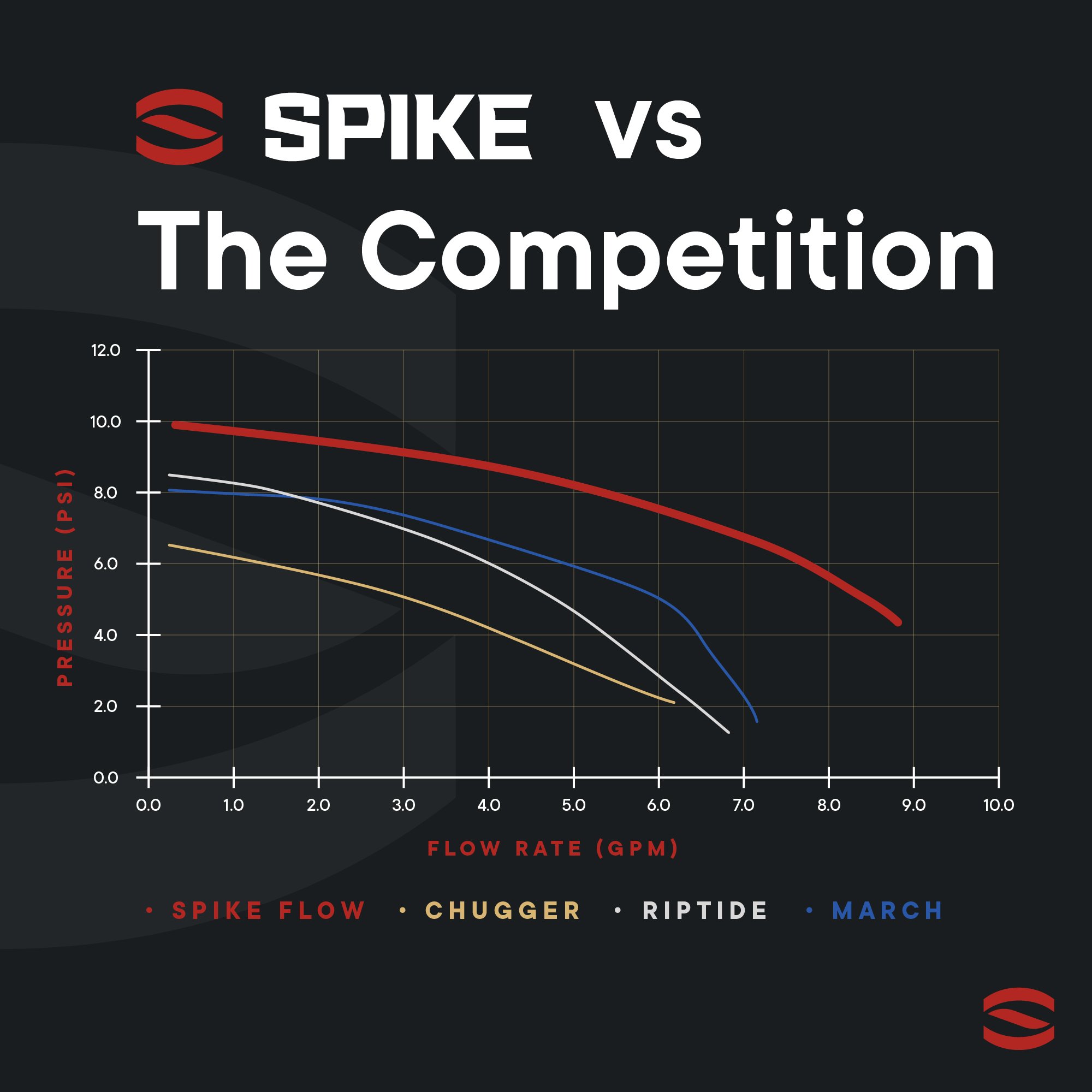

Higher Pressure & Flow-What's more important? Moving your wort quickly or a powerful CIP? The Spike Flow is leading at both. No compromises here.

Air Relief Valve-Air in your lines creating headaches? The Flow features an ARV bleed system. Problem solved.

Clog Proof Impeller-With the built-in chopping tines on the impeller, you'll never have to stop mid-Brew Day because of a clogged pump head.

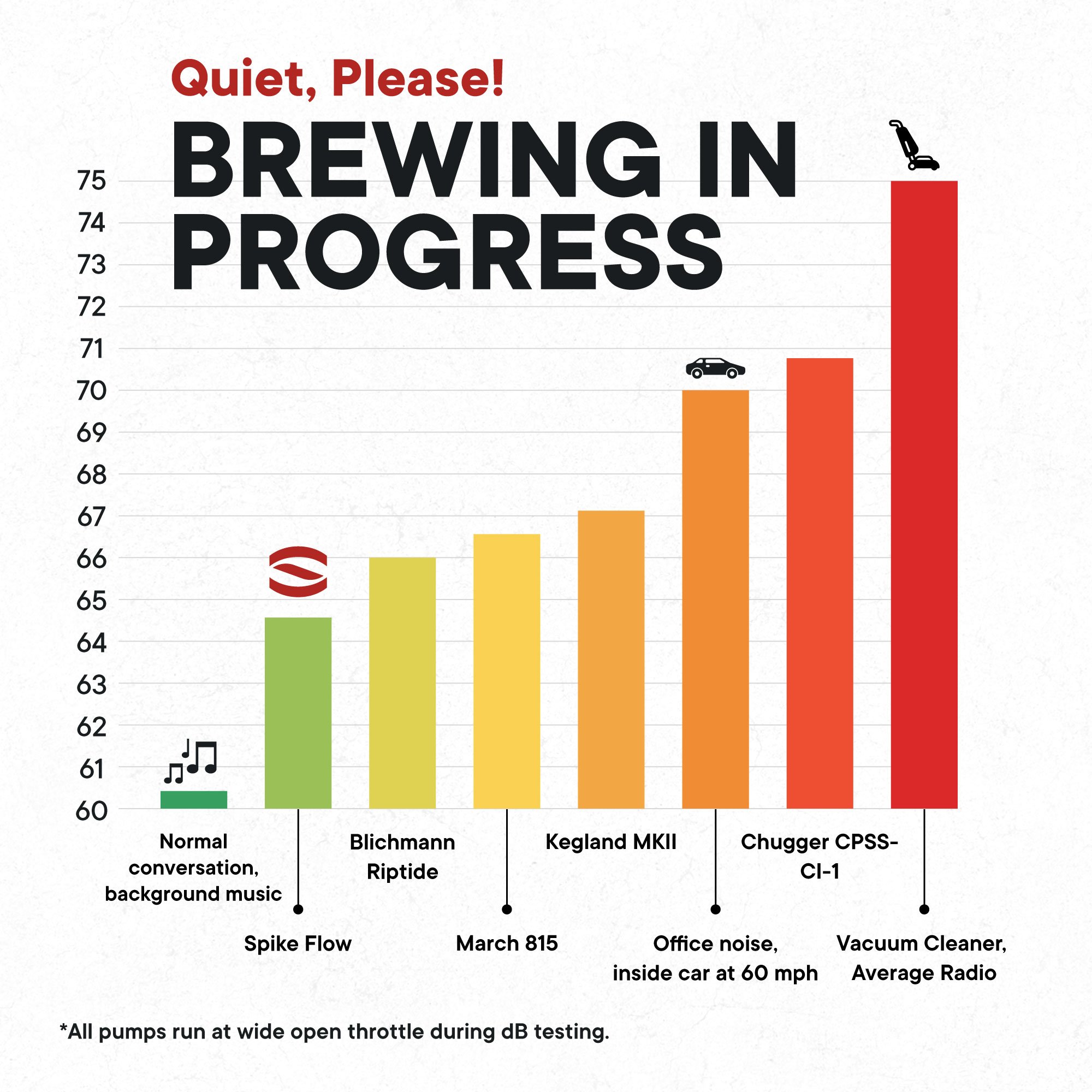

Quietest on the Market-The Flow is for brewers who prefer listening to their brewing playlist or the game on TV rather than a loud pump.

Specs:

• Best-in-class 9GPM (gallons/minute) flow rate

• Best-in-class 9.5 PSI of pressure (22' of head)

• Air Relief Valve (ARV) makes priming easy and convenient

• Built in 1/2" drain barb

• 6-vane impeller design optimized for performance and durability

• 304 stainless steel precision machined casting with maximized inlet and outlet ports

• Integrated chopping tines to prevent clogging

• Proprietary FDA black treatment applied to the pump head

• Black anodized motor shell

• Easy disassembly, cleaning and reassembly

• Ultra-quiet, fan enclosed motor: 120v, 60 Hz, 1.5A

• 6 foot power cord

• 9" length x 5" width x 7" height

• Continuous use rated

Reviews

- Reviews

- Questions

Fatal design flaw - is this a known cause of pump failure?

A disaster strikes. The pump stopped working in the middle of HERMS heating. Disassembled and found it won’t spin due to no or lack of clearance between the impeller (E) and the Rear Housing (D). The impeller was grinding against the housing. Repaired - an emergency repair to be clear - with a washer, stainless steel washer for now. The pump works as it should. I’d find the same washer made of Teflon -PETEFT. Is this a known failure? Cheers, Richard

Good pump

I bought this pump because my inline Chugger pump just didn't seem to have enough "oomph" with the Spike CIP ball in my CF10. To be fair, it still worked, I just wasn't thrilled with the pressure. The Spike flow definitely has a much better flow rate and higher pressure than the Chugger. It is not loud and I like how the bleed valve is engineered. The only bummer thing - and this certainly was not Spikes fault - was that USPS shipped the unit to within a few miles of house in Michigan, then put it on an airplane to California, then to 3 cities in California, before putting it on a slow truck back across the country to my house. So if Spike gives you an option - definitely don't pick USPS for shipping.

Built like a brick

I am truly enjoying this pump. Because of operator error I thought the filling valve was defective. Customer support suggested that I press in in before I attempt to close it. They were absolutely correct and it’s functioning flawlessly. It is truly made of heavy duty sturdy stuff. I expect to use it until I wear out.

This pump is amazing!

Great Pump!

Great pump, very quiet and powerful. The purge valve is very handy. Using two of these now.

Air Relief Valve

Placing a purge valve on the inlet side of the pump provides the best way of getting air out of your pump head and hoses. Just twist the easy to grip knurled knob, then water and air start to flow through the ARV outlet.

We even placed a little barb in the pump head casting that faces front and center, so it's easy to collect fluid out of the barb and dump it back into your kettle. Since the inlet of the pump doesn't produce any pressure, the valve can be open even when the pump is flowing and you won't get sprayed.

Higher Pressure

Why is higher pressure better? Well, high pressure makes for better cleaning when using a CIP ball. It also helps give a better whirlpool when running through a chiller. It helps move your wort quickly when pumping through hoses, which ultimately shortens your Brew Day.

Higher Flow

7,874 feet of 3D printer filament and almost 100 pump prototypes designs...that's what was required as part of developing the Spike Flow pump head. The was crucial for achieving our industry-leading performance goals. We invested in further techniques such as clear SLS prints (so we could see and visualize the water and air flow through the housing) and CNC machined parts to be able to run hot water and wort testing before our casting tools were ready for prime time.